Condition Monitoring.

Detect, project + optimize.

Understand machine performance, predict + prevent breakdowns, and improve safety.

Understanding machine performance in real-time across a production line and factory can unlock all-new optimization possibilities.

Machine failures, maintenance regimes not based on actual data, and sub-optimal configurations all lead to inefficiencies, financial costs and lost production time - not to mention workplace incidents and injuries. Our Condition Monitoring module gives you complete transparency and enables you to implement predictive maintenance regimes, transforming asset efficiency, worker safety and improving productivity.

Easy-to-use, ready-to-deploy and fully interoperable with your existing technologies; Condition Monitoring allows your organization to be one step ahead and plan maintenance before failure - all-round, it'll save you time, money and effort.

See for yourself: schedule a demo

Discover how easy, affordable and transformative our Condition Monitoring module can be for your business.

Remember, all of our modules are:

- Ready-to-deploy

- Affordable - even at scale

- Easy-to-use and accessible by anyone, anywhere

- Can be up and delivering in weeks.

Condition Monitoring features: succeed out-of-the-box.

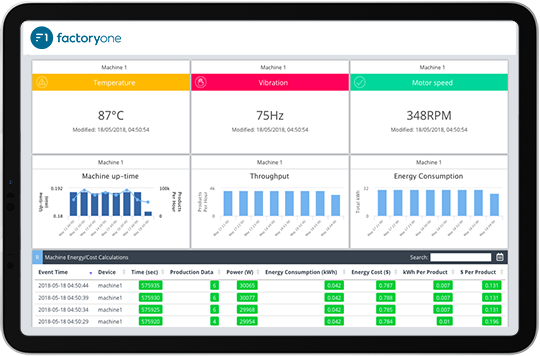

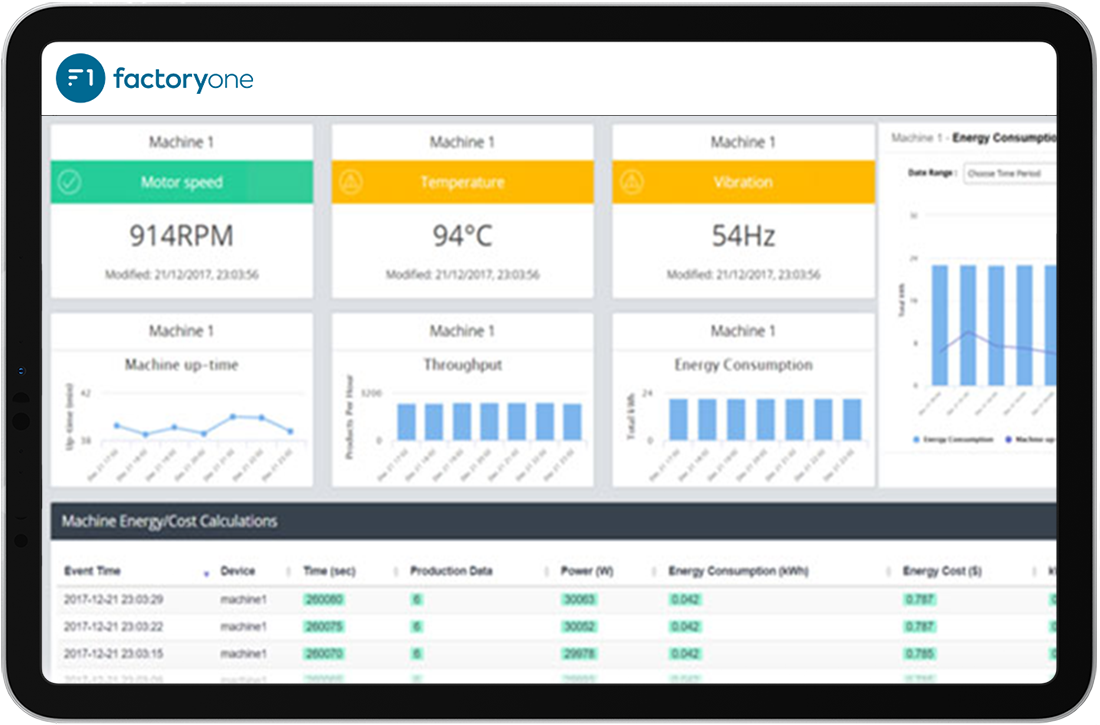

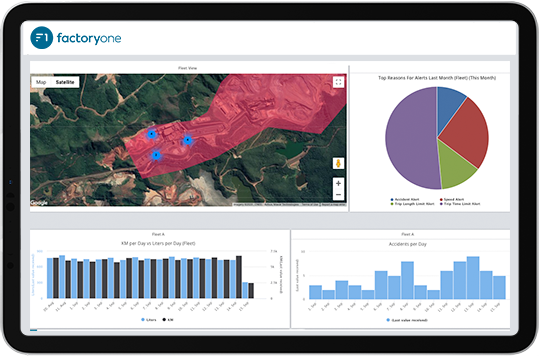

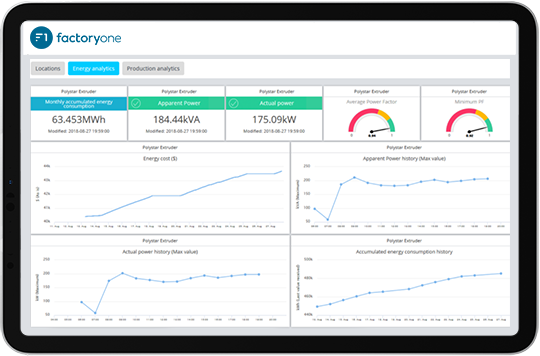

Machine-level condition monitoring + health analytics on any device, anywhere.

Real-time status + detailed machine metrics via interactive dashboards.

Real-time alerts + notifications.

Comparative machine health at-a-glance.

Timeline views of machine status + machine health.

Efficiency suggestions + pre-configured machine learning for ongoing optimization.

Custom workflow creator.

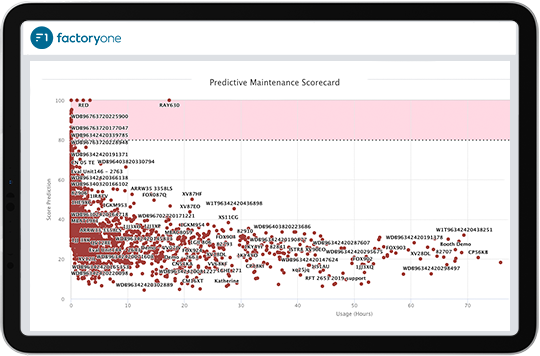

Automations + AI-led interventions: Industry 4.0-ready.

Condition Monitoring delivers real business outcomes, fast:

Monitor performance in real-time

Predict failures

Reduce maintenance

Prevent unplanned downtime

Enable smarter maintenance planning

Increase workplace safety

Included as-standard in all Factory One solutions:

API

Integration

ERP

Integration

Custom Workflows, Machine Learning

+ Automation

Enterprise

Security

Edge + SaaS Deployment

No Minimum

User Limits

Find out more about the core platform Condition Monitoring is built on: Dynamix.

Why Factory One.

All-in-one +

ready-to-go

Easy-to-use

+ scale

100% Interoperable: no new hardware

Complete Industry 4.0 toolkit

Enterprise security

as-standard

Future-proof, SaaS-based technology

Deploy anywhere,

fast

Affordable

for all

Factory One works with best-in-class partners to deliver manufacturing solutions anywhere in the world: